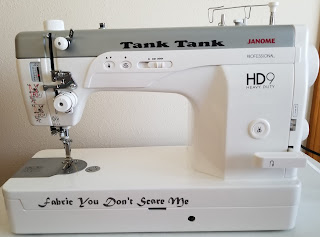

Tank Tank - My Janome HD9 Professional

I have plenty of Janome sewing machines so why did I need (want) another? One of my frustrations has been not enough penetration power when going over bulky seams. I have learned how to adjust but there have been a few times I resorted to hand sewing and I loathe hand sewing.

What's laughable is I bought the Janome Memory Craft 6700P because when I tested it at the dealer - it went through bulky seams with no problem. At the dealer I put the pedal to the metal and went for it. When I bought mine home I was too afraid to do that with my machine - I did not want to "hurt" my machine.

Why the name Tank Tank? It reminds me of an army tank. I can pick it up by myself but it is heavy and in my mind indestructible.

When I decided that I needed single needle heavy duty sewing machine I originally intended to purchase an industrial one from my dealer. I realized the table it came in did not have wheels and that was the deal breaker for me. I move stuff around, in and out of my sewing room all the time and I needed to be able to do that with this machine. After playing with a couple of machines I decided on the HD9 because it sewed thru bulky seams so smoothly.

I love love love this machine. Guess what - it's a tank so I am not afraid to put the peddle to the metal and sew with it because it is indestructible. It does one thing and it does it well - it sews a beautiful straight stitch.

One of the things that I have always loved about Janome is they understand automatic tension. Even though this is a manual tension machine - I have not had to adjust it (except the stitch length). I have used regular polyester thread and heavy weight thread (30 wt and 12 wt) and get beautiful straight stitches each time.

I have this machine sitting on a cheap plastic table and even at high speeds it does not move - it's a solid machine (a tank).

On regular machines the foot needs to be level for properly formed stitches. not Tank Tank. There have been times when the foot was at a 45 degree angle and it just pushed right through those bulky seams.

Initially I thought threading this machine would be hard, but it is a breeze.

This machine is not afraid of any fabric hint hint the tag line "Fabric You Don't Scare Me". Tank Tank says bring it on.

There are a couple things that need to be improved.

What's laughable is I bought the Janome Memory Craft 6700P because when I tested it at the dealer - it went through bulky seams with no problem. At the dealer I put the pedal to the metal and went for it. When I bought mine home I was too afraid to do that with my machine - I did not want to "hurt" my machine.

|

| Matching Cover I Made For It |

Why the name Tank Tank? It reminds me of an army tank. I can pick it up by myself but it is heavy and in my mind indestructible.

When I decided that I needed single needle heavy duty sewing machine I originally intended to purchase an industrial one from my dealer. I realized the table it came in did not have wheels and that was the deal breaker for me. I move stuff around, in and out of my sewing room all the time and I needed to be able to do that with this machine. After playing with a couple of machines I decided on the HD9 because it sewed thru bulky seams so smoothly.

I love love love this machine. Guess what - it's a tank so I am not afraid to put the peddle to the metal and sew with it because it is indestructible. It does one thing and it does it well - it sews a beautiful straight stitch.

One of the things that I have always loved about Janome is they understand automatic tension. Even though this is a manual tension machine - I have not had to adjust it (except the stitch length). I have used regular polyester thread and heavy weight thread (30 wt and 12 wt) and get beautiful straight stitches each time.

I have this machine sitting on a cheap plastic table and even at high speeds it does not move - it's a solid machine (a tank).

On regular machines the foot needs to be level for properly formed stitches. not Tank Tank. There have been times when the foot was at a 45 degree angle and it just pushed right through those bulky seams.

Initially I thought threading this machine would be hard, but it is a breeze.

This machine is not afraid of any fabric hint hint the tag line "Fabric You Don't Scare Me". Tank Tank says bring it on.

There are a couple things that need to be improved.

- Needle threader - I am sure I will eventually understand it but right now it 50/50. One of the reasons is the needle hole is left to right rather than front to back.

- Bobbin Insertion - It's not really the bobbin insertion but more of threading the bobbin. The bobbin is half a bobbin (really Janome) and it normally takes me 2 or 3 times of putting it in and re-threading it before I get it right.

- Presser Bar Doesn't Lift High Enough - I think it should go a little higher. There have been a couple times I struggled to get all the bulk under the foot.

Even with the above irritations - I still love this machine. It does exactly what I need it to do and that is go through bulky seams seams with ease.

I had a moment of temporary insanity - this is the first machine of three bought in a two week time period. I will review the others later.

Comments

Post a Comment

Enter comments here